Robroy Industries PVC-Coated Explosion-Proof Fittings UL 1203 Listed

Superior Adhesion and Structural Integrity offer Best Possible Corrosion Protection while Maintaining Original Intent of Hazardous Location Fitting

Robroy Industries PVC-Coated Conduit and Fittings has enhanced its line of hazardous location fittings in order to provide customers with the safest and best performing corrosion resistant solution for hazardous location areas. Robroy Industries Sealing Fittings, Conduit Unions, GUA Outlet Boxes, and EC Series Flexible Couplings are now verified for safety through UL 1203 Listings; the UL Safety Standard for Explosion-Proof and Dust-Ignition-Proof Electrical Equipment for Use in Hazardous (Classified) Locations.

Hazardous location fittings are required in classified areas where failure is not an option as it could result in costly expenditures and more importantly loss of life. Proper selection of UL listed and ETL verified products that offer both proven safety and proven performance is vital to support on-going operations.

The external PVC coating, internal urethane coating and factory thread protection of the conduit and fittings enhance the protection in corrosive environments, while allowing the system to function as intended in hazardous locations. The proprietary internal urethane coating is specially formulated by Robroy Industries allowing for a consistent measured thickness and ultimate flexibility, while still offering the best coefficient of friction in the industry. Rigorous Erosion Testing was performed to verify the performance and adhesion strength of the urethane coating to guarantee long-term safe operation of the fittings in hazardous locations.

In addition to product testing, Robroy Industries is also an ISO 9001 facility which guarantees the adherence of a consistent quality program and thus, a consistent manufactured product. ISO 9001 is a recognized quality management system (QMS) and is the only ISO standard that requires certification. ISO Certification is a seal of approval from a 3rd party body that a company runs to one of the internationally recognized ISO management systems. It is a business model that is based on numerous quality management principles including a strong customer focus, management leadership, a disciplined process approach and continual improvement with the end goal of consistent quality.

PVC coated hazardous location fittings carrying the UL 1203 listing are available immediately through Robroy Industries and include conduit unions, outlet boxes, EC series flexible couplings and sealing fittings.

Conduit Unions

Conduit Unions allow for better transitions within hazardous locations and are used in order to connect conduit in areas where the conduit cannot be turned. They also allow for future changes to the system. The threads of the unions are designed to perform two critical functions for a joined conduit system. First, they act as a grounding path for the system’s electrical continuity and second, the threads provide a flame path that vents and dissipates any gasses contained within the properly installed system.

GUA Outlet Boxes

GUA series outlet boxes serve as pull and splice boxes and also provide future access to conductors for maintenance and future system changes. Outlet boxes are equipped with a gasketed seal which prevents liquid and vapors from entering the fittings. The threads on hazardous location outlet boxes also act as a system ground and flame path, venting and dissipating any gasses contained within the fitting.

EC Series Flexible Couplings

EC series flexible couplings aids in accomplishing difficult bends and allows for movement and vibrations of connected equipment. Additionally the rugged design is able to withstand explosive pressure and mechanical abuse. EC series flexible couplings are also liquid-tight for wet locations and come with the option of two threaded male end fittings or a female union and male threaded end fitting.

Sealing Fitting with Patent Pending P5SA™ Visual Validation System

Sealing Fittings are used in conduit runs to stop gasses, vapors, or flames from migrating from one part of the system to another. This limits the spread of any potential explosion, enhancing safety. Sealing fittings are available with several different options, such as breathers and drains to accommodate installation in various locations and positions. The new patent-pending P5SA™ feature allows positional feedback for the upgraded urethane-coated plug for proper installation without compromising the best possible corrosion protection. To validate proper installation and plug engagement, the new design allows for visual validation by ensuring the plug will not protrude beyond the beveled edge of the PVC around the plug, validating that there are 5 full threads of engagement per the NEC code, which is critical for safe installation and a proper flame path. Sealing fittings are UL listed to use with either traditional Chico® A or Chico® Speed Seal™ Sealant Compounds and require proper tagging after installation to ensure correct classification ratings.

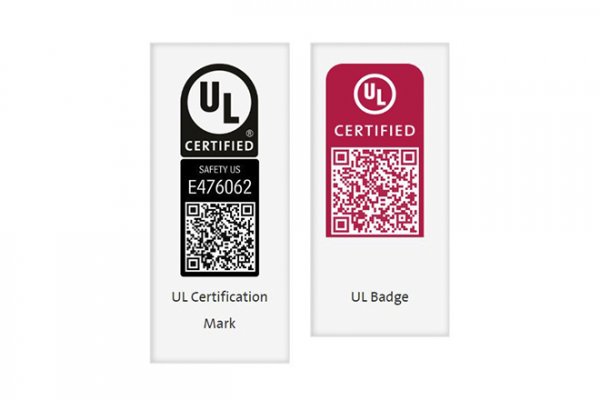

Products are labeled according to the requirements of UL 1203 for the hazardous locations in which they are listed for use. All listed Robroy Industries PVC coated hazardous location fittings are also equipped with the Enhanced UL Certification Mark on their label. Enhanced UL Certification Marks provide streamlined access to the UL Smart Marks Hub, which provides important compliance data, product information and proper installation instructions via smart devices.

Robroy Industries offers a complete line of PVC coated conduit, fittings and accessories providing proven, maximum protection for electrical systems in corrosive environments.